Corrugated boxes have become the backbone of e-commerce and global trade. They are so common that we often overlook them as just a simple means of “holding things.” In reality, these unsung heroes protect goods from crushing forces, vibrations, moisture, and dust during transportation. The best part? They do all this while being lightweight, foldable, recyclable, and cost-effective. It’s no surprise that nearly 95% of the world’s products are shipped in corrugated boxes. While they quietly drive supply chains and modern commerce, have you ever wondered how they are made?

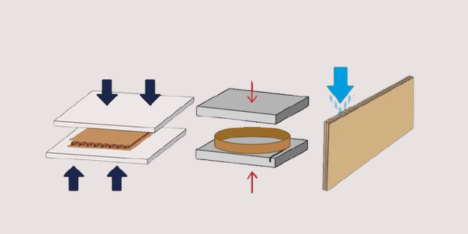

Corrugated board is made from two main components: linerboard and a fluting medium, both crafted from kraft paper.

-

The linerboard forms the flat outer and inner surfaces of the board.

-

The fluting medium is shaped into a wave-like pattern (flutes) and sandwiched between the liners.

This ingenious structure gives corrugated boxes their much-needed strength, cushioning, and stacking ability. A well-made box can support several hundred times its own weight, all while remaining lightweight and economical. To ensure performance, paper mills evaluate several quality parameters. Since fibers are blended in different ways (virgin, recycled, or with additives), it’s critical to understand how these variations affect paper strength.

One of the most important properties is the crushing strength of paper. It involves conducting various strength tests to the liner and fluting media to get key insights into the product being made. A box made with low-strength paper can collapse prematurely during transit, damaging its contents. By analyzing crush test data, manufacturers can fine-tune fiber bonding and grammage, producing stronger paper without over-engineering the product. This benefits from balanced cost and performance. This is where the Lab Crush Tester becomes essential. It is a precision compression testing instrument designed to evaluate the strength and durability of paper, paperboard, and corrugated packaging. By measuring resistance to crushing forces, it provides valuable insights into material performance.

The crush tester can perform a wide range of standardized tests, each revealing a different aspect of paper or board strength. One such test commonly performed is the Ring Crush Test (RCT) which measures the edgewise compression strength of paper and paperboard by compressing it in a ring form. The results provide insights into the fiber bonding and rigidity of the material. Similarly, the enhanced design of the equipment allows users to conduct further compression tests, including Flat Crush Test (FCT), Edge Crush (ECT), Concora Crush Test (CCT), Concora Medium Test (CMT), Pin Adhesion Test (PAT), and Score Quality Test (SQT).

How do you perform a Crush Test?

Step 1: Sample Conditioning

Before testing, specimens must be properly conditioned to stabilize their moisture content. Conditioning ensures accuracy and consistency across tests. According to TAPPI T 402, samples are first exposed to a preconditioning atmosphere, then conditioned at 23 °C ±1 °C and 50% RH ±2% in a Humidity/Environmental Chamber (Model: UEC-5003). This eliminates variability caused by environmental factors such as humidity.

Step 2: Sample Preparation

Samples must be cut to the exact test dimensions defined by the relevant standard. Precision cutting prevents dimensional variations that could affect test results. Specialized cutters ensure fast and accurate preparation. For example, the Sample Strip Punch and Die Cutter (UEC-1009 C) produces a 12.7 × 152 mm strip in one punch — ideal for the Ring Crush Test (RCT).

Step 3: Sample Placement

Because paper is thin and flexible, it can buckle under load. To avoid this, specimens are placed in specialized jigs/fixtures before testing. The jigs ensure samples are held properly and well supported during compression. This ensures tests are accurate, repeatable, and comparable across different labs and mills.

Step 4: Sample Testing

The fixture containing the specimen is placed centrally between the compression platens of the crush tester. A controlled compressive load is applied at a defined speed until the sample buckles or fails. The maximum load (Fmax) is recorded in Newtons (N) or pounds-force (lbf). This value is converted into crush resistance according to the test type (RCT, ECT, FCT, etc.).

Step 5: Sample Analysis

The results of the test are displayed on the screen along with the deformation level. The results can be printed or transferred to a PC for further analysis. Some advanced versions of the instrument, such as the Lab Crush Tester NexGen (UEC-1026BII), report various other parameters, including the flat crush stiffness, hardness, energy absorption, score ratio, etc.

Test Capabilities

The Lab Crush Tester can perform the following crush tests according to the relevant test standards.

-

RCT (Ring Crush Test) – Measures the edgewise compressive strength of paperboard.

-

ECT (Edge Crush Test) – Determines the stacking strength of corrugated board.

-

CCT (Concora Crush Test) – Assesses medium strength after fluting.

-

CMT (Corrugating Medium Test) – Tests the strength of fluted paper under compression.

-

FCT (Flat Crush Test) – Evaluates the flatwise resistance of corrugated board.

-

PAT (Pin Adhesion Test) – Measures adhesion strength between corrugated layers.

-

SQT (Score Quality Test) – Evaluates the strength of the scoring/creasing along the fold lines of the corrugated sheet.

Who is it for?

The Lab Crush Tester is an essential tool for companies that need to guarantee packaging strength, consistency, and reliability. Accurately simulating real-world compressive forces, it helps businesses maintain quality control and deliver durable packaging solutions across multiple sectors.

Industries that benefit from crush testing include:

-

Packaging & Printing Manufacturers – To validate paper and board strength before conversion.

-

Corrugated Box Manufacturers – To predict stacking performance and prevent packaging failures.

-

Paper Mills – To monitor fiber bonding, grammage, and overall material quality.

-

Consumer Goods Companies – To ensure packaging protects products throughout the supply chain.

-

Logistics & E-Commerce – To safeguard goods in transit, reduce damage rates, and maintain customer satisfaction.

What are the differences in the offerings?

Depending on budget and feature requirements, customers can choose between two high-performance models of the Lab Crush Tester: the LW Lab Crush Tester (UEC-1026 BI) and the NexGen Lab Crush Tester (UEC-1026 BII). Both are built with high-quality materials, ensuring accurate, consistent results and low ownership costs.

Lab Crush Tester LW (UEC-1026 BI)

A cost-effective solution designed for essential testing needs.

The Lab Crush Tester LW (lightweight variant) is designed to provide a simplified, user-friendly interface with only the essential reporting parameters. It uses our next-generation lightweight platform that simplifies test reporting. Users can conduct accurate testing of paper, paperboard, and corrugated board for RCT and get compressive strengths readings for ECT, CCT, FCT, PAT & CMT tests. It can also perform compression tests on small packages (mono cartons).

Lab Crush Tester NexGen (UEC-1026 BII)

A premium, fully digital solution for labs seeking automation, detailed analytics, and IoT-enabled workflows.

Our Lab Crush Tester Nexgen (Next Generation variant) further enhances the capabilities of the lightweight platform by delivering a highly sophisticated IoT-based platform that provides unmatched capability to any other offering. Users are offered an intuitive interface on a large high resolution touch screen that comes with 7 test programs pre-installed from the factory. The programs have been individually optimized to make it easier to conduct the tests and get further vital insights into the test data, along with a graphical display of the force curves. Additionally, enhanced digitalization allows faster measurements with precision. The intelligent platform calculates the correct peak load automatically and converts it into useful data instantly to provide accurate test results. With a single click, users can generate detailed test reports, transfer the data to a PC wirelessly, or print the test results.

With the growing demand for safe, reliable, and sustainable packaging, the crush test has become the gold standard for evaluating the physical properties of paper, paperboard, and corrugated materials. By investing in a high-quality crush tester, manufacturers not only gain accurate insights into material performance but also reduce the time and effort spent adjusting production parameters. The result is paper that consistently meets performance requirements at a lower manufacturing cost, ensuring stronger packaging and improved supply chain reliability. If you are considering a Lab Crush Tester for your operations, we would be glad to assist you. Simply visit our Contact Us page and connect with our team.